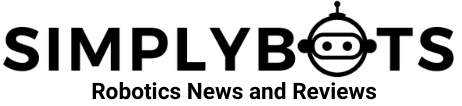

Boston Dynamics released a new video showing its humanoid robot, Atlas, executing complex tasks without human input. This demonstration signals a new phase in Atlas’s development, as it uses advanced artificial intelligence (AI), 3D vision, and machine learning to perform industrial tasks autonomously, positioning it as a potential asset for manufacturing and logistics.

In the video, Atlas moves large automotive parts, maneuvering them between bins with precision and adaptability. Using sensors, Atlas can detect obstacles, realign items, and adjust movements, effectively overcoming errors like collisions. This illustrates how the robot’s autonomy extends beyond movement to environmental responsiveness. Equipped with a specialized three-fingered gripper, Atlas can securely hold various objects, making it practical for warehouse or manufacturing environments.

Atlas represents Boston Dynamics’ vision for robotics in industry. While earlier iterations showcased the robot’s athletic abilities—like running and leaping—this release underscores its potential in practical applications. Competing with initiatives from companies like Tesla, which is developing the Optimus robot, Boston Dynamics focuses on creating robust, independent machines for industrial roles.

As Atlas progresses, Boston Dynamics reaffirms its influence in the robotics landscape, prompting discussions about automation’s role in industry and its impact on human labor. The company’s advancements showcase how robots like Atlas could redefine workflows, taking on labor-intensive roles and contributing to a more efficient, technologically advanced industrial ecosystem.