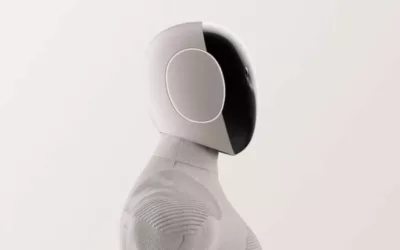

Mercedes-Benz is ushering in a new era of production with its latest addition to the workforce: a 5-foot-8, 160-pound humanoid robot capable of lifting 55 pounds and autonomously recharging during breaks.

Austin-based humanoid robot manufacturer Apptronik, has secured a significant contract to supply its Apollo robots to Mercedes-Benz for their production line.

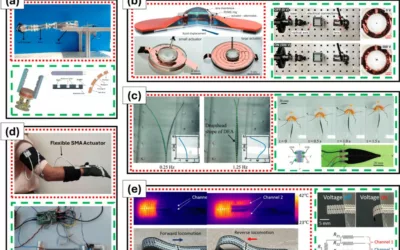

According to the joint announcement by Mercedes-Benz and Apptronik, the carmaker is exploring various applications for the Apollo humanoid robots in its logistics operations. These robots will assist in transporting parts to the production line for assembly and conducting component inspections. Additionally, they will reportedly be responsible for delivering totes of kitted parts essential for the manufacturing process.

Apptronik CEO Jeff Cardenas expressed optimism about the potential of these systems, stating, “Long term, really the sky’s the limit in terms of what these types of systems will be able to do.” Apollo robots are specifically designed to collaborate with human workers, emphasizing a symbiotic relationship between man and machine.

This collaboration between Mercedes-Benz and Apptronik is part of a larger trend in the robotics industry. Other companies, such as Figure and Agility Robotics, are also making strides in integrating humanoid robots into industrial settings. For instance, Figure’s robots are joining BMW’s manufacturing plant in South Carolina, while Agility Robotics’ Digit has been deployed at various facilities, including Amazon and Spanx distribution centers.

Apptronik’s partnership with NASA further underscores the potential of humanoid robots beyond Earth’s factories. By accelerating the commercialization of Apollo, this collaboration aims to push the boundaries of robotics technology.

However, amidst these advancements, there remains a lingering concern about the impact on human employment. Mercedes-Benz and Apptronik emphasize that Apollo is intended to automate physically demanding, repetitive, and monotonous tasks, supplementing the workforce rather than replacing it. This strategic approach acknowledges the evolving needs of the auto industry while ensuring the continued relevance of human workers in manufacturing processes.