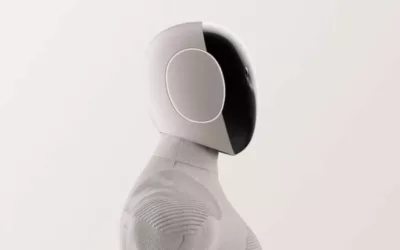

ABI, a Dutch company renowned for its ABIFlexx delta robots, has unveiled its latest innovation: the ABIFlexx with direct drive technology. This advancement provides exceptional speed, pinpoint accuracy, noiseless operation, and less maintenance.

ABI designs and manufactures the Delta robot range, known for its ability to meet the most stringent processing requirements. These modular delta robot designs come in various configurations, including the patented Wide Delta robot, which conserves up to 50% of floor space but also offers an efficient working range.

Direct drives offer advantages over traditional motor and gearbox combinations. They are energy-efficient and exceptionally precise, with no backlash issues. By eliminating conventional oil-based gearboxes, they eliminate mechanical limitations and durability concerns, resulting in a maintenance-free, silent, rapid, and precise robotic solution.

The ABIflexx Delta robot excels in production processes where hygiene is paramount. Whether it’s for the retrieval and positioning of unpacked products, the automatic fitting and assembly of components, or the precision cutting of food, the three motor drives of the standard ABIflexx model execute tasks swiftly and consistently.

For greater flexibility, the addition of a grab rotation is easily achievable. This grab rotation is seamlessly facilitated by a direct drive system fully integrated into the gripper plate.