Circuit breaker arc flash incidents pose a significant risk in the United States, with an estimated 30,000 occurrences annually, resulting in one to two fatalities daily in North America alone. In an effort to enhance safety protocols, Ontario Power Generation (OPG) deployed five Boston Dynamics’ Spot robots within their Enterprise Innovation division. The robots were initially tested to assist in tripping and racking out a 600-volt breaker, a high-risk activity for arc flash incidents. The success of this initial trial has led Boston Dynamics engineers to take automation to the next level, enabling Spot to autonomously perform the entire operation, while human operators issue high-level commands safely from a distance.

The Importance of Arc Flash Safety

Arc flash incidents, characterized by the release of high-energy arcs, can cause severe burns, injuries, and even fatalities. It is crucial for industries and power generation facilities to implement stringent safety measures to protect workers from these hazardous events.

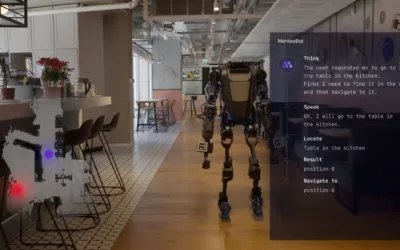

Spot in Action

The partnership between OPG and Boston Dynamics has proven beneficial in addressing arc flash safety concerns. Spot, with its advanced robotic capabilities, demonstrated its potential as a valuable asset in high-risk scenarios. By utilizing Spot’s dexterous arm and advanced mobility, OPG aimed to minimize human exposure during critical operations.

Automation Takes Center Stage

In 2022, OPG’s focus shifted towards automating the tripping and racking out procedure. Boston Dynamics’ engineers worked diligently to equip Spot with the necessary intelligence to autonomously execute the operation. The fully automated process now allows Spot to perform the task without the need for direct human intervention, significantly reducing the risk of arc flash incidents.

Safety Advantages of Spot’s Automation

The automated procedure not only ensures worker safety but also enhances efficiency and precision. Spot’s accuracy and repeatability in executing tasks reduce the likelihood of human errors, leading to improved overall operational safety.

Human-robot Collaboration

While Spot operates autonomously during the procedure, human operators remain involved through high-level commands. This collaborative approach enables workers to supervise and control Spot’s actions from a safe distance, ensuring utmost precaution during critical operations.

Real-World Applications and Potential Impact

The reported success of the Spot robots in arc flash safety has implications for various industries. Beyond power generation facilities, these autonomous robots could be deployed in high-risk environments such as chemical plants, oil refineries, and manufacturing facilities. By delegating dangerous tasks to robots, companies can enhance worker safety, reduce workplace accidents, and improve operational efficiency. As robotic technology continues to progress, Spot and its counterparts are set to revolutionize workplace safety across various sectors, ultimately leading to a safer and more efficient work environment.