MIT announced their scientists have made a groundbreaking advancement in robotics with the development of miniature soft-bodied robots that can be easily controlled using a weak magnet. These robots, constructed from flexible magnetic spirals, can be programmed to perform various movements such as walking, crawling, and swimming, all in response to a simple magnetic field.

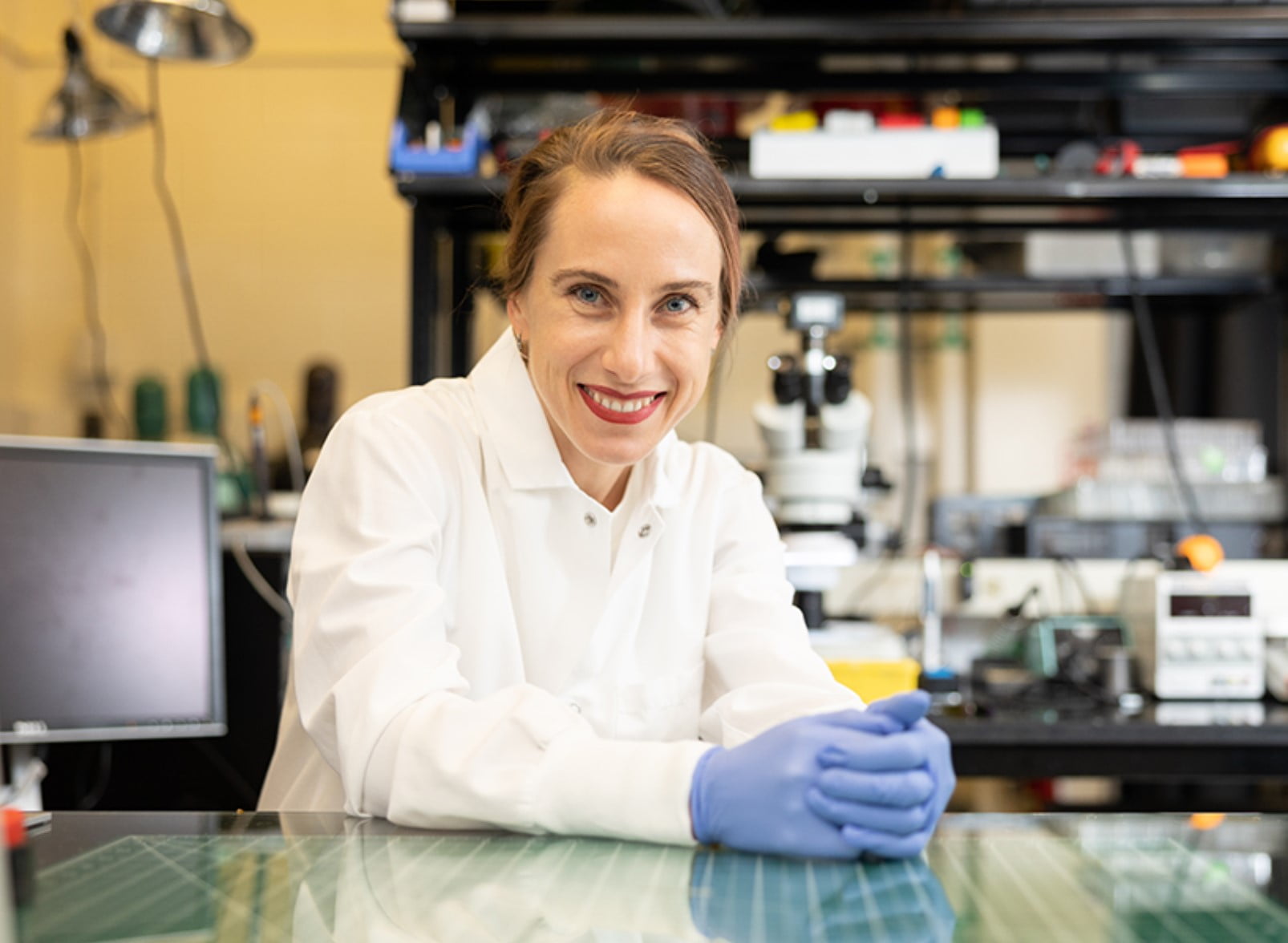

In a recent open-access paper published on June 3 in the journal, Advanced Materials, Professor Polina Anikeeva and her team at MIT described their pioneering work on these magnetic robots. Professor Anikeeva, who is a professor of materials science and engineering and brain and cognitive sciences at MIT, explained, “This is the first time this has been done, to be able to control three-dimensional locomotion of robots with a one-dimensional magnetic field.” She further emphasized that the robots’ soft composition, predominantly made of polymer, allows them to be activated by a very small magnetic field.

The new robots have demonstrated capabilities for transporting cargo through tight spaces, and their rubber bodies are gentle on delicate environments. This opens up the possibility of developing this technology for biomedical applications. While the current robots are millimeters in size, Professor Anikeeva believes that the same approach could be used to create even smaller robots.

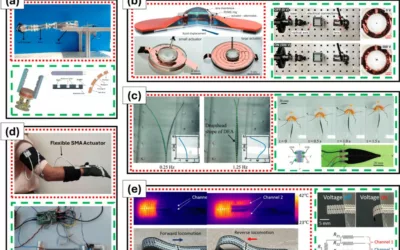

Engineering the magnetic robots posed a unique challenge. Traditionally, magnetic robots respond to moving magnetic fields, meaning the magnet must move along with the robot to control its motion. However, this limits the robots’ applications, particularly in constrained environments where a moving magnet may not be safe. To overcome this limitation, Youngbin Lee, a former graduate student in Professor Anikeeva’s lab, developed a solution. Instead of uniform magnetization, the robots are strategically magnetized in different zones and directions. This way, a single magnetic field can generate a movement-driving magnetic force profile.

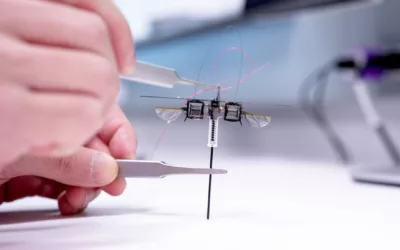

Before magnetization, the robots’ flexible and lightweight bodies are fabricated. Lee begins the process by using two types of rubber with different stiffness, which are layered, heated, and stretched into a long, thin fiber. Due to the differing properties of the rubbers, one layer contracts while the other cannot return to its original size. As a result, the fiber coils tightly when the strain is released, resembling the spiral tendrils of a cucumber plant.

A third material, capable of becoming magnetic, is incorporated into a channel running through the rubbery fiber. Once the spiral shape is formed, a magnetization pattern is introduced to enable specific types of movement. Careful calculations are made to establish the desired profile of forces on the robot when a magnetic field is applied, allowing it to walk or crawl.

For example, to create a crawling robot resembling a caterpillar, the helical fiber is shaped with gentle undulations, and the body, head, and tail are magnetized. When a magnetic field perpendicular to the robot’s motion is applied, the body compresses. Releasing the field allows the robot to stretch, propelling it forward. In another design, two foot-like helical fibers connected with a joint enable a walking-like movement when magnetized in a specific pattern.

This precise magnetization process generates a program for each robot, ensuring easy control once they are constructed. Each robot’s program is activated by a weak magnetic field, driving its particular movement. Interestingly, a single magnetic field can simultaneously set multiple robots in motion, even in opposite directions if programmed accordingly. The team discovered that a slight manipulation of the magnetic field can be used to advantage, allowing a cargo-carrying robot to gently shake and release its payload by simply flipping a switch to reverse the field.

Professor Anikeeva envisions various applications for these soft-bodied robots. Their simple production process makes scaling up easy, and they could be utilized for delivering materials through narrow pipes or even inside the human body. For example, they could transport drugs through narrow blood vessels and release them precisely where needed. Furthermore, magnetically-actuated devices have biomedical potential beyond robotics and might one day be integrated into artificial muscles or materials that support tissue regeneration.