Today Boston Dynamics announced a number of new software and hardware upgrades to Spot. With over 1000 robots deployed across 35 countries, Spot is at the forefront of the emerging mobile robotics market. In response to the growing need for better data collection and improved efficiency, Spot has introduced a range of new features and hardware to enhance its capabilities. These advancements include automated inspection solutions for thermal monitoring, acoustic leak detection, and gauge reading, as well as improved inspection workflows and enhanced human-robot interactions.

Industrial Inspections: New Features and Hardware

With Spot’s automated inspection solutions, tasks such as thermal monitoring, acoustic leak detection, and gauge reading are now easier than ever. The latest features in the Scout software allow for remote mission planning and editing, providing better visibility into work sites. Additionally, Spot’s improved visual and audio features ensure safer operations on busy job sites, while new manipulation capabilities open the door to more autonomous missions.

Inspection Workflows

With the latest software updates, visual, thermal, and acoustic inspections have never been simpler. The new release offers multiple simultaneous inspection types and an updated inspection configuration workflow, ensuring a seamless user experience. Boston Dynamics’ aim is to enable customers to have Spot working on-site within a few hours, generating value from the first week of deployment.

Thermal Inspection

This feature not only triggers Scout notifications when equipment exceeds preset ranges but also enables users to capture multiple regions of interest in a single photo. With enhanced inspection review capabilities, users can compare temperatures across the entire photo and set up alerts for temperature differences between different regions. This functionality is particularly useful for inspections where multiple targets should maintain the same temperature.

Gauge Reading: Visual Inspections

Spot Robotics integrates visual inspections, specifically gauge reading, into its new software release. Through a partnership with Levatas, Spot can inspect analog gauges across various sites, monitor trends in Scout, and trigger alerts for abnormal readings. This eliminates the need for manual monitoring or replacing analog gauges with digital versions, resulting in significant cost savings and improved efficiency for customers like GlobalFoundries, BP, and National Grid.

Acoustic Imaging

Spot has fully integrated acoustic imaging capabilities into its latest release. By utilizing the Fluke SV600 payload, Spot can trigger acoustic inspection actions directly from the tablet and evaluate inspection results remotely through Scout. The SV600 serves as an early warning system, enabling users to swiftly identify and address problem areas. With the ability to set alarms for air and gas leaks or changes in sound signatures, businesses can proactively save on energy costs, prevent equipment failure, and ensure uninterrupted operations.

Scout: Remote Inspection Software

Scout serves as Spot’s solution for mission editing, scheduling, real-time data reviews, and data transfer to your asset management system. To enhance collaboration and provide deeper insights into operations, Spot has added new features such as permissions sets and a dashboard to review robots’ progress. With Scout, businesses can optimize their operations and harness the full potential of Spot’s capabilities.

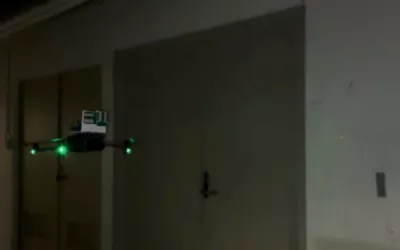

Human-Oriented Hardware: Enhancing Safety and Interaction

Boston Dynamics has prioritized the development of human-oriented hardware to enhance safety and interaction between Spot and human workers. The redesigned hardware includes an audio and visual signaling system, providing enhanced safety and awareness in industrial settings. Safety lights, a safety buzzer, and a speaker embedded in the robot’s body alert workers to Spot’s actions. The system features pre-configured light patterns and tones for different scenarios, ensuring people near the robot know what to expect. Additionally, a physical emergency stop button has been added to the back of the robot, further enhancing safety measures.

Behavior Enhancements: Improved Stability and Object Detection

Spot’s gait has been modified to ensure safer movement on slippery surfaces and wet floors. In crawl mode, Spot moves one leg at a time, staying close to the ground to maintain stability. The introduction of moving object detection allows Spot to identify and react to moving objects such as people or forklifts, ensuring increased caution and safe navigation during missions.

Autonomous Manipulation: Opening New Doors

Spot Arm, previously used for manual manipulation tasks, can now autonomously open doors during Autowalk missions. This beta feature opens up new inspection routes and allows Spot to move autonomously between rooms, even in empty facilities.

Boston Dynamics has added a number of very useful additions to the Spot platform including thermal monitoring, acoustic leak detection, and gauge reading, as well as improved inspection workflows and enhanced human-robot interactions. These enhancements should increase the adoption of this platform for use in the autonomous monitoring of plants and equipment. We look forward to seeing what is “next” in the continual evolution of Boston Dynamics’ Spot.